The Essential Commercial Greenhouse Supplies Checklist

What exactly goes into setting up a commercial greenhouse grow? Besides the important preliminary steps, like selecting a location, acquiring permits and picking out the right greenhouse materials, operations will also need to go through the process of planning out their production space.

During this phase of a project, one of the challenges growers are tasked with is curating a list of essential commercial greenhouse supplies. Greenhouse operations require a wide variety of equipment and accessories, ranging from smaller, more basic items that every grower relies on, to the larger components that allow their structure to function properly year-round.

The ideal mixture of products will ultimately depend on several factors, including where a greenhouse is based, the type of business growers are looking to run and the plant varieties they intend on cultivating. No matter the scenario, operations can use this checklist to ensure they have the appropriate tools at their disposal, so they can establish a productive and profitable commercial greenhouse grow.

COMMERCIAL GREENHOUSE SUPPLIES: CLIMATE CONTROL EQUIPMENT

Climate control is a year-round concern, and it’s important that growers have the right commercial greenhouse supplies on hand to combat the changes in season. For cooling purposes, this means taking advantage of active ventilation equipment and dedicated cooling systems.

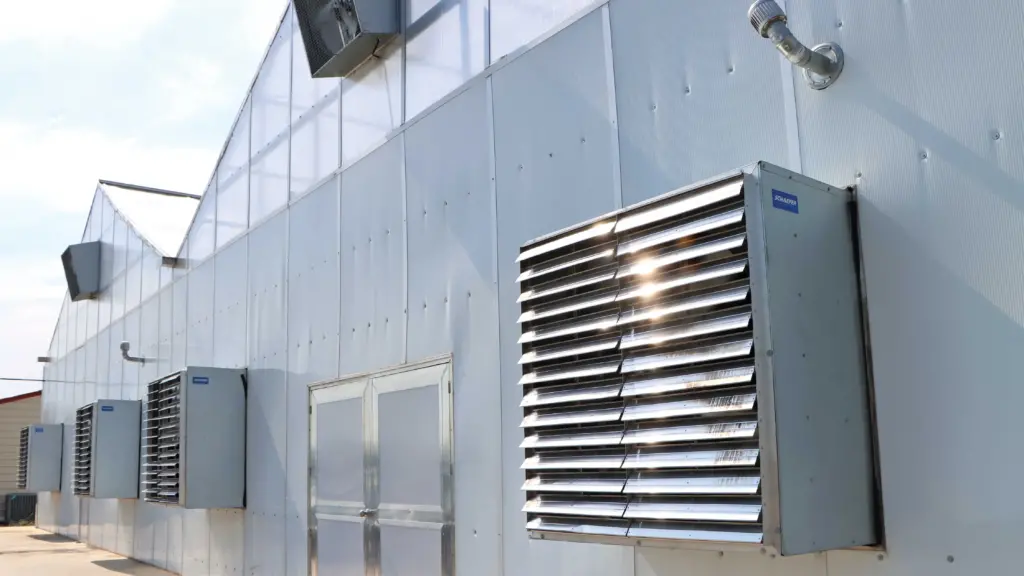

An effective greenhouse design will account for passive ventilation, but to truly optimize airflow, operations should employ a combination of exhaust fans and horizontal airflow fans (HAF). Exhaust fans are installed on the end walls of a greenhouse and function by drawing in air from the outdoors into the structure. The best high-performance exhaust fans will enable growers to maximize air output, without significantly increasing their energy consumption.

HAF fans are designed to help circulate air across a greenhouse, mixing hotter air from the gable area with cooler air towards the ground level. With a series of HAF fans working in unison, even growers with extra-long greenhouse bays can avoid warm air pockets and maintain consistent temperatures, making these an essential part of any commercial greenhouse supplies checklist.

When it comes to commercial cooling systems, many growers turn to the evaporative cooling method. A traditional fan and pad setup uses exhaust fans to pull in hot air from the outdoors, and as it passes through the system’s wet wall, the air is chilled by water-soaked pads and distributed across the structure at canopy level. Compared to other solutions, this is a powerful cooling option that supplies valuable air movement, consumes little energy and requires no additional pumps, filters or internal plumbing.

Temperature control during the winter months is largely dependent on a structure’s thermal efficiency, as well as a properly sized heating system. Although insulation is primarily determined by greenhouse cladding, growers can work with their greenhouse supplier to design a heating system that produces consistent temperatures amidst the cold season, no matter the scale of their structure.

Forced air heaters tend to be one of the most common commercial greenhouse supplies for cold-climate growers. In these units, heat is generated by air passing over a heat exchanger using a fan or blower, and they are powered by an operation’s choice of electricity, propane or natural gas.

Growers in regions with more mild winters may also benefit from incorporating radiant heating into their structure. Radiant heating systems, a type of infrared heater, require piping to be installed under a greenhouse’s foundation and must be connected to a hot water heater.

As the system heats the air between the floor and foundation, it rises naturally and radiates throughout the greenhouse space. This style of heating system can be used to heat an entire structure, or growers can use it strictly for under-bench heating, supplying warmth right to a plant’s root mat.

COMMERCIAL GREENHOUSE SUPPLIES: IRRIGATION SYSTEMS

Optimizing water and nutrient delivery is going to be a priority in any greenhouse, and for commercial growers, there are a number of systems available to choose from. Different water delivery methods suit various applications, so operations will want to gauge the needs of their desired crop type before purchasing the necessary commercial greenhouse supplies.

With today’s emphasis on efficiency and sustainability in agriculture, drip irrigation has become one of the most widely used watering methods. Drip irrigation systems employ thin tubing that helps supply water directly to soil or growing media in specified quantities, delivering the optimal amount right where it matters most.

This method is also ideal if growers plan on implementing fertigation equipment, rather than relying on more traditional fertilization techniques. By combining fertigation with drip irrigation, operations are able to get water and nutrients to plants’ root zones through one delivery method in a precise and controlled manner, enhancing growth and reducing waste.

While drip irrigation is right for some growers, other operations may find that an overhead irrigation system is the most sensible solution for their greenhouse. These can be an effective option with crops that are able to withstand wet foliage.

Two of the most popular overhead watering methods are sprinkler systems and boom watering systems. Sprinkler systems utilize a series of pipes, which are installed above an operation’s crops, and are then equipped with nozzles to provide coverage over an entire growing space.

Boom watering systems are driven by a motor and feature a large boom that spans from one side of a greenhouse bay to the other. These setups allow for more uniformity than a greenhouse sprinkler and are popular for large-scale monocrop productions and generating seedlings grown in plug trays.

Growers also have the option of installing hydroponics systems throughout their greenhouse. Hydroponics systems eliminate the need for soil by delivering a water-based nutrient solution to crops; although, certain systems often include an aggregate substrate, like coco coir, peat, perlite or mineral wool. Hydroponics is a commonplace practice in some of the largest greenhouse grows and is known for its energy-efficiency, sustainability and high output.

Sign Up Now To Learn More

COMMERCIAL GREENHOUSE SUPPLIES: BENCHING & SHELVING

Greenhouse benching and shelving can play a key role in the overall functionality of a commercial structure. It is also a design element that will vary greatly, depending on the type of greenhouse growers are looking to run.

In a retail setting, growers will want to be mindful of their benching setup, so they can optimize production space, while also leaving plenty of room for customers to browse. Operations can implement certain layouts to help improve this, along with their ideal combination of stationary, rolling and tiered benching.

Conversely, growers with a greenhouse dedicated solely to production should ensure they have the maximum amount of growing space. Rolling benches can be an effective solution that enables workers to add or eliminate walkways with ease as they tend to plants. Other operations may want to take advantage of an automated solution, like mobile containers, which allow them to change the entire organization of their greenhouse in just a few moments.

It’s important to note that, if growers plan on incorporating hydroponics into their structure, benching becomes somewhat of an unnecessary expenditure. Systems like NFT channels, ebb and flow or vertical aeroponics do not require any form of benching to support plants. However, Dutch Bucket systems pair well with low-profile benches, as these can place taller vine crops at the perfect working height.

COMMERCIAL GREENHOUSE SUPPLIES: SUPPLEMENTAL GROW LIGHTS

One of the hallmarks of greenhouse production is access to natural sunlight. To truly optimize growth, though, operations will likely need some form of supplemental lighting.

Light fixtures ensure that, no matter the time of year or variety of crop being grown, operations can provide their plants with the optimal amount of light to help them reach their full potential. Still, there are a variety of lighting options available for growers to choose from, so it’s important they understand the primary differences between the most prevalent lighting styles.

High pressure sodium fixtures promote budding and flowering and are most beneficial later in a plant’s growth cycle. They are far more efficient than incandescent bulbs and work best when used in conjunction with natural daylight, making them a valuable option for greenhouse operations. To achieve the best results, growers will generally want to mount these lights 30 to 36 inches above their plants.

LED fixtures are highlighted by their long lifespan and energy-efficiency, even when used as a sole source of lighting. Majority of their power output goes to light instead of heat, which enables them to have such a high efficiency rating. High-quality LED lights offer a typical lifespan of 50,000 hours and can provide up to 70% energy savings when compared to high-intensity discharge (HID) lighting.

Although they appear bright-white to the human eye, ceramic metal halide lights are utilized for their blue light. Growers often employ these fixtures in the early phase of a plant’s life, when seeds are in their vegetative growth phase. They have an average lifespan of 8,000 to 15,000 hours and feature a dimmable ballast, which allows growers to obtain the ideal lighting level for their needs.

Lastly, T5 fixtures continue to be one of the most efficient and popular fluorescent lighting options. They consume less energy than traditional lamps, can last up to 50,000 hours and are able to be used from the initial seed starting phase, all the way to full term growth. High-performance T5 fixtures can provide full spectrum lighting with minimal heat output, so they can be placed very close to plants, generally within a range of 6 to 12 inches.

GrowSpan is the ultimate one-stop shop for commercial greenhouse supplies of any kind. From custom lighting packages and powerful, yet efficient climate control systems to even the smallest accessories, including pots, containers, seed starting trays, growing media, pest control products and more, growers can outfit their structure with everything they need in one convenient location.

For help selecting the right commercial greenhouse supplies for your grow, call or Request a Quote today.

Related Articles

Implementing Greenhouse Shelving To Optimize Growing Space

Although it may be an afterthought for some growers, greenhouse shelving and benching has become one of the most important greenhouse accessories.

Understanding Your Greenhouse Watering System And Irrigation Management

Most growers know that in any commercial operation, an effective greenhouse watering system is one of the keys to a successful harvest.

Cooling A Greenhouse: Everything You Need To Know To Beat The heat

During the summer months, growers need the right systems in place to bring temperatures down, cooling their greenhouse in a reliable, yet energy-efficient manner.

The Basics Of Fertigation: How Growers Can Implement Fertigation Systems

Traditional fertilization methods can be painstaking for growers, especially those in larger commercial operations.

LOoking To Operate A Year-Round Greenhouse? Here's How

When operations want to grow crops in a year-round greenhouse, the requirements for doing so can be vastly different, depending on their location.

Understanding Greenhouse Lighting

Growers have a wide array of lighting options to pick from, so it’s important to understand the nuances of differing lighting styles.